Peristaltic pumps are widely recognized for their unique pumping mechanism, making themsuitable for a range of applications across different industries. In this article, we will explore the Peristaltic Pump Original Equipment Manufacturer (OEM) market and delve into the features, benefits, and diverse applications of peristaltic pumps as OEM solutions

Understanding Peristaltic Pumps

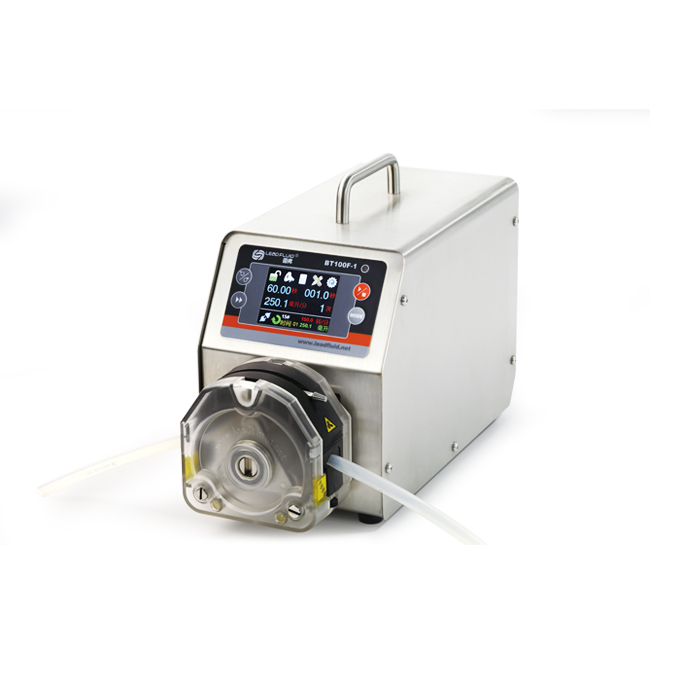

- Operating Principle:Peristaltic pumps utilize a rotating roller or shoe mechanism to compress and relax a flexible tube, creating a peristaltic motion that propels fluids. This gentle pumping action ensures precise and consistent flow rates while avoiding direct contact between the pumped fluid and the pump components.

- Tube Selection and Versatility:Peristaltic pumps offer versatility through their compatibility with various tube materials, sizes, and configurations. This allows for the handling of different fluids, including corrosive or sensitive substances, without risk of contamination or damage to the pump.

Benefits of Peristaltic Pump OEM Solutions

- Accurate and Reliable Fluid Transfer

Peristaltic pumps provide accurate and repeatable flow rates, making them ideal for applications that require precise fluid transfer, metering, or dosing. The peristaltic pumping action ensures minimal pulsation and shear forces, preserving the integrity of sensitive fluids. - Gentle Handling of Shear-Sensitive or Viscous Fluids

The gentle pumping action of peristaltic pumps minimizes shear forces, making them suitable for handling shear-sensitive fluids such as cell cultures, pharmaceutical solutions, or delicate emulsions. Additionally, peristaltic pumps excel at transferring viscous fluids or those containing particulates without clogging or damage. - Self-Priming and Dry Run Capabilities

Peristaltic pumps are self-priming, meaning they can draw fluid into the tube without the need for external priming. This feature simplifies setup and eliminates the risk of dry running, protecting both the pump and the fluid being transferred. - Easy Maintenance and Cleanability

Peristaltic pumps feature a simple design with minimal moving parts, facilitating easy maintenance and quick tube replacement. The tube is the only component in contact with the fluid, simplifying cleaning and reducing the risk of cross-contamination.

Applications of Peristaltic Pump OEM Solutions

- Medical and Pharmaceutical Industry:Peristaltic pumps find extensive use in drug delivery, diagnostics, and bioprocessing applications. They provide precise and sterile fluid transfer for pharmaceutical formulations, laboratory automation, tissue engineering, and chromatography systems.

- Food and Beverage Production:Peristaltic pumps are utilized for the transfer and dosing of food ingredients, flavorings, additives, and beverages. Their gentle pumping action preserves the integrity and quality of the products, making them suitable for handling sensitive or delicate fluids.

- Water and Wastewater Treatment:Peristaltic pumps play a vital role in water and wastewater treatment processes. They are used for chemical dosing, sample collection, and sludge handling, offering accurate and reliable fluid transfer in harsh and demanding environments.

- Chemical and Industrial Processes:Peristaltic pumps are employed in various chemical and industrial applications, including metering of acids, solvents, and abrasive fluids, as well as transferring viscous materials, lubricants, and polymers. Their compatibility with a wide range of chemicals and materials makes them versatile for numerous process requirements.

- Laboratory and Research:In laboratory and research settings, peristaltic pump OEMs are employed for tasks such as liquid handling, sample preparation, and continuous flow experiments. Their versatility, ease of use, and compatibility with various tubing materials make them valuable tools for researchers and scientists.

Peristaltic pump OEM solutions offer a versatile and reliable fluid transfer solution across multiple industries. Their accurate dosing, gentle handling of sensitive fluids, self-priming capabilities, and ease of maintenance make them highly sought-after for applications ranging from medical and pharmaceutical to food and beverage production, water treatment, and chemical processes. As technology continues to advance, peristaltic pumps will undoubtedly play an increasingly important role in meeting the fluid transfer needs of diverse industries.